Sun protection

The building blocks of an effective sunscreen

We've already provided information about ingredients, classifications and INCIs here on our sun page. But what are the actual functions of these ingredients? What do the individual building blocks of a sunscreen do?

A good sunscreen should naturally provide effective protection against the harmful effects of the sun’s UV rays. But the overall requirements for cosmetic products are much higher.

- Fulfillment of the performance profile

- Good skin tolerance

- Attractive texture

- Optimal sensory properties

- Formulation stability

- Pleasant smell

The right composition of ingredients is required to achieve this, with this formulation of various components then serving the requirements for the product.

In addition to the sun protection factor, photostability and sensory effect, it is important to consider the trend of formulating and manufacturing sun protection in accordance with environmental sustainability.

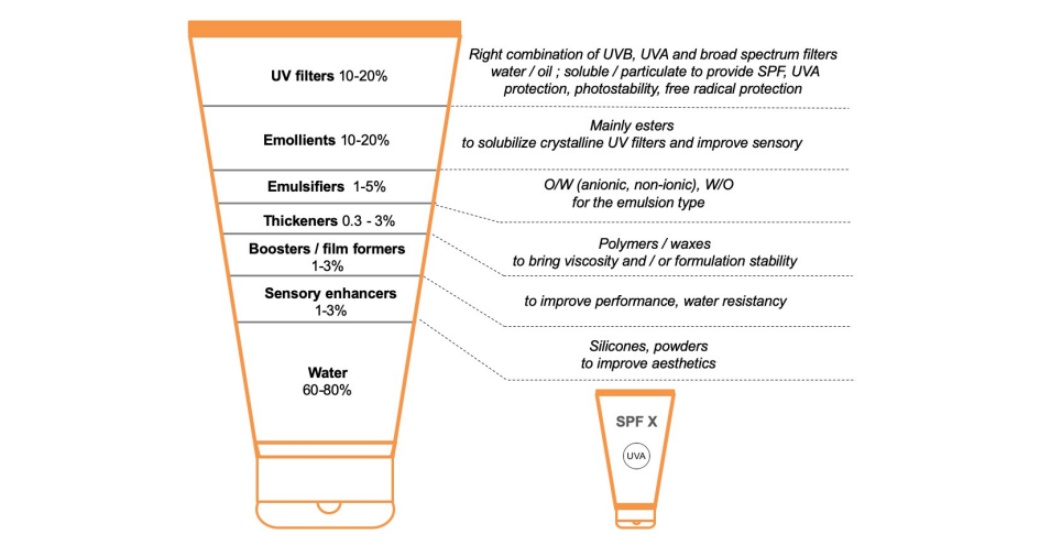

But let's go back to the individual components and building blocks of a sunscreen formulation. Core competencies include UV filters, emollients and emulsifiers. What is their role?

UV filters

In essence, a sun protection product consists of a mixture of several UV filters. It is not unusual for up to 6 different UV filters to be used. This is done in order to achieve the right performance over the entire UV range (UVB + UVA). The absorption capacities of the UV filters vary in terms of the different wavelengths. They can absorb either in the UVB, the UVA or the entire UV range (broadband). Combinations are now used to obtain the best possible protection. UV filters can be soluble or particulate and must be photostable so that they are not destroyed under UV light and, for example, create free radicals. They are naturally essential in sunscreen, as there is no sun protection without a UV filter.

Emollients

Emollients (mainly esters) are used to solubilize crystalline UV filters. Complete solubility of powdery filters is required for their efficiency and ensures homogeneous distribution of UV filters in the formulation. They are also responsible for the sensory effect and have a major influence on how it feels on the skin. Fast-spreading emollients are smooth immediately after application. Slow-spreading emollients feel less smooth, but remain noticeable over a long period of time.

Emulsifiers

An emulsifier is a substance (tenside) that creates and stabilizes an emulsion. An emulsion is a mixture of different liquids that can only be mixed together with difficulty. Using emulsifiers keeps both phases together. These components have a lipophilic and a hydrophilic part. As a result, the emulsifiers can place themselves directly at the boundary between the water and the oil phase and hold them together. Emulsions exist as water in oil when the inner droplets are water and the external phase is oil, or as oil in water when the inner droplets are oil and the external phase is water. An O/W emulsion generally feels lighter than a W/O emulsion. What we definitely know: Milk, butter, cream and mayonnaise are emulsions from the food sector.

In addition to the aforementioned components, other components play a role in the market-ready product. Thickeners, amplifiers/film formers, sensory amplifiers and water are also required to provide a complete sunscreen formulation.

- Thickeners

By using these polymers, waxes and/or gums, also called rheology modifiers, the viscosity and spreadability of the end product are determined and created. They also increase the stability of the formulation. - Amplifiers/film formers

Their main task is to improve the performance and water resistance of the sunscreen. - Sensory amplifiers

The so-called sensor amplifiers are used to improve and optimize the sensory effect. They are usually added to the formulation as a powder or silicone derivative to make the aesthetics and sensation on the skin as comfortable as possible, and to reduce stickiness and oiliness. The product will feel velvety and silky afterwards.

To bring the optimum sun protection product with the best possible effect to the market, the building blocks must harmonize. Important factors: The UV filter system, the correct dispersion and solubilization of UV filters in the emulsion, and finally the uniform distribution of UV-absorbing molecules on the skin. The sun protection film should be as even as possible after application.

If everything fits, you will not only very well protected but the sunscreen will feel very pleasant.

What exactly are SPF, LPF and so on?

When buying sunscreen, the majority of consumers pay most attention to the sun protection factor. This value is tested directly on humans via what is known as an in vivo process. However: A high sun protection factor alone does not mean a sunscreen is good.

More information